Lapping Calcite

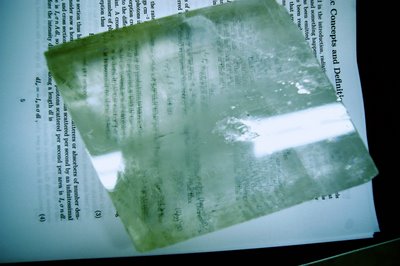

I learned how to polish (lap) surfaces in our "adaptive-optics" lab. Basically, you use sandpaper to grind the surface down to a very fine grit, and then use a "slurry" to polish the surface the rest of the way. I stopped at 1-micron grit. The surface came out quite nice. I've got a giant piece of calcite - maybe 6"x6" that was a total pain to polish, but it's really clear.

Here's the polishing lab - lots of grinding gear. We can grind our own flat surfaces here at the IfA. I don't actually know what they use it for, but they let me play.

Here's the polishing lab - lots of grinding gear. We can grind our own flat surfaces here at the IfA. I don't actually know what they use it for, but they let me play. Birefringence is cool...... double images! This piece was very junk looking on the outside but turned out awesome.

Birefringence is cool...... double images! This piece was very junk looking on the outside but turned out awesome.  Here's the "lapping pads" - you use one of those water bottles with some grit-powder-water-mix and put some on one of the rubbery pads and then grind away. It kills your shoulders and wrists.

Here's the "lapping pads" - you use one of those water bottles with some grit-powder-water-mix and put some on one of the rubbery pads and then grind away. It kills your shoulders and wrists.  I actually had a good reason to use this lab - I needed to test some "goo" I'll be using for an infra-red spectropolarimeter and I needed some flat surfaces on some other calcite pieces. I just decided to borrow the equip for an extra little project. Neat.

I actually had a good reason to use this lab - I needed to test some "goo" I'll be using for an infra-red spectropolarimeter and I needed some flat surfaces on some other calcite pieces. I just decided to borrow the equip for an extra little project. Neat.

0 Comments:

Post a Comment

<< Home